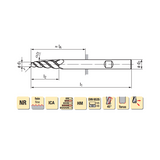

3° Taper / 6.5mm - 4 Flute Solid Carbide Through Coolant Tapered Torus End Mill Turbine - Emuge Franken

3534LZ.03065A

Turbine tapered carbide torus end mill for roughing applications in high-strength materials, and nickel-based or titanium alloys.

Product features and benefits:

- Design with four flutes and 3° taper angle.

- Ideal for pre-machining turbine components or other complex 5-axis components made of aluminium, titanium or Inconel.

- Variable flute spacing for low-vibration machining.

- ALCR coating for longer tool life, very well suited for high-alloyed materials.

- High performance tool.

- Roughing profile.

- Low-vibration machining.

- Suitable in all turbine materials.

- Optimised for machining Impellers and Integrated Bladed Rotors (IBR) made from aluminium, titanium and Inconel.

- Not available on next day delivery, please contact us to check availability if urgent. Standard delivery is 2-3 business days.

| Taper Angle (α/2) | 3° |

| Cutting Diameter (Ød1) | 6.5mm |

| Radius (r1) |

1mm |

| Cutting Length (l2) | 14mm |

| Projecting Length (la) | 32mm |

| Overall Length (l1) | 68mm |

| Shank Diameter (Ød2) | 8mm |

| Shank Diameter Tolerance | h6 |

| Flutes (Z) | 4 |

| Tool Interface | Straight shank with side-lock clamping flat |

| Tool Interface Norm | DIN 6535 |

| Coating | ALCR |

| Internal Coolant Supply | Axial Through Coolant |

| Helix Angle | 45° |